Introduction

The weaving and dying craft is the process of making cloth which is made by crossing two sets of threads over and under each other. The two sets of threads are called warp and weft. The saree, popular apparel amongst Indian women, is a part of the weaving and dying craft. Many varieties of shining threads are immersed in dyes before weaving. This entire process constitutes the weaving and dying craft. Natural dyes like the indigo are used widely since the ancient times. However, in modern times the chemical dyes are gaining priority over the vegetable and mineral dyes.

The weaving and dying craft is the process of making cloth which is made by crossing two sets of threads over and under each other. The two sets of threads are called warp and weft. The saree, popular apparel amongst Indian women, is a part of the weaving and dying craft. Many varieties of shining threads are immersed in dyes before weaving. This entire process constitutes the weaving and dying craft. Natural dyes like the indigo are used widely since the ancient times. However, in modern times the chemical dyes are gaining priority over the vegetable and mineral dyes.

Different forms of Weaving and Dyeing Craft

The styles of weaving and dyeing craft vary depending upon the cultural tradition of the place, climatic conditions, cultural influences and business contacts. India has a wide range of textiles of varied designs that are manufactured by numerous techniques when compared to other countries in the world. Weaving and dyeing is done in India with the help of different materials and each state has its own style. For instance, the weaving and dyeing style of East India has a huge variety in the usage of materials like the silks brocades whereas cottons are prevalent in the West.

Bandhani style

The Bandhani and Tie-and-Dye culture is popular in the states of Rajasthan, Gujarat and Madhya Pradesh. This pattern is followed by intricate designs made by the womenfolk of the states. The Bandhani work is highly acclaimed in the centers like Kutch, Mandvi and Bhuj. Moreover, the Khatri community of Gujarat is known for their fine quality dyeing. Kutch is a well known centre for some sarees like the Gharchola sarees that bear tied and dyed patterns.

Traditionally bought for weddings, these sarees carry a gold thread for the checks with small golden motifs like peacock or lotus in the center. Rajkot in Saurashtra and Jamnagar are other important centers for Bandhanis. Jodhpur, Jaipur and Sikar in Rajasthan are famed for their Bandhani and Tie and Dye work in India.

Traditionally bought for weddings, these sarees carry a gold thread for the checks with small golden motifs like peacock or lotus in the center. Rajkot in Saurashtra and Jamnagar are other important centers for Bandhanis. Jodhpur, Jaipur and Sikar in Rajasthan are famed for their Bandhani and Tie and Dye work in India.

Mothra and Lahriya style

Mothra and Lahriya techniques are some of the other well known techniques of Rajasthan. The techniques and styles are different in Bihar and are worked to create bold patterns in single colors. The same technique is used in Madurai in Tamil Nadu to produce the famous Sungudi saris, which are a must for many communities during marriages in the South.

Patola style

The tie and dye technique of threads before weaving is known as Patola which is internationally known as Ikat. This type of weaving is done in Andhra Pradesh and Odisha. In Andhra it is known as Pagdu Bandha Baddabhasi or Chilka. Ikat furnishing weaving is done in the whole of Nalgonda district of Andhra. Moreover, Odisha has a distinctive style of Ikat popularly known as Bandha.

Batik style

Another well admired weaving and dying process is known as Batik that involves painting of the fabric with molten wax and then dying in cold dyes. This is said to be one of the most ancient techniques of weaving and dying process, carrying the tradition of 2000 years. Batik is done on a large scale in Madhya Pradesh and the items of this process include multi-colored batik saris, dupattas and bed sheets which are popular for their contrasting color schemes.

Textile printing craft

Block-printing, on the other hand includes hand printing which is widely practiced in Jaipur, Sanganer, Bagroo, Apli and Barmer in Rajasthan. In Gujarat, Mandvi, Dhamardhka, Mundra, Anjar, Jamnagar, Surrendranagar, Jaitpur, Ahmedabad, Baroda and Deesa are the important centers of printing fabrics. Mandvi and Anjar in Kutch district of Gujarat use both direct printing as well as resist printing.

Delhi and Farukhabad in Uttar Pradesh are also famous for printing establishments. Including these, Mausilipatnam in Andhra Pradesh has printers who are specialized in hand printing, Kalamkari printing, Resist printing, block printing and Batik works as well. Tanjore in Tamil Nadu produces fine quality hand printed saris with the resist method in a village which is called Kodial.

Jamdani style

The weaving and dyeing craft has got a distinct style in West Bengal with cotton. These sarees are called Jamdani and they follow the traditional patterns of weaving which is still practiced in Tanda and Varanasi. This Jamdani technique of patterning is found in the cotton centers of Venkatagiri in Andhra, Morangfi in Manipur and Kodialkarruppar in Tamil Nadu as well. Maheshwar on the banks of the river Narmada weaves fine cotton sarees with tiny checks, the Illkal sarees of Karnataka and the Narayanpet sarees of Andhra also follow the same style.

Gold brocade style

The weaving and dyeing craft has been recognized in Varanasi due to its associated famous silk weaving centers. The specialty of the region is the heavy gold brocade, which has an extra weft of rich gold thread running across the warp threads. Varanasi is preferred for the Amru silk brocades which are the Butidar ones enclosed by a border and a heavy pallu of flowering bushes or the flowing mango pattern.

Baluchar style

Another technique which is based upon the miniature paintings of India is Baluchar technique of Murshidabad district of West Bengal. The technique is popular in sarees known as Baluchari sarees.

Other weaving styles

There are some of the places where weaving and dyeing craft in cotton saree is considered of attracting the fancy of the people like Gadwal, Wanaparti, Nander and Venkatagiri. Even the cotton sarees produced in Tamil Nadu closely resemble the silk ones and the centers where these saris are manufactured are Kanjeevaram, Salem, Pudukottai and Madurai. Coimbatore has its own style which are less expensive and which resemble the Chanderi patterns. Nowadays cotton sarees woven with the traditional silk patterns called Kalakshetra is widely popular. The cotton sarees of Kerala are popular as Karalkudi. These are made of unbleached cotton with rich broad gold borders and pallus have become popular nowadays.

Apart from these, Ridrol in Mehsana District and Jamnagar in Saurashtra in Gujarat have centers of silk weaving. South India has a distinct class of its own in silk sarees. Kancheepuram, Tanjore and Kumbakonam are the important silk centers in Tamil Nadu. Sangareddy in Andhra, Kolegal and Molkalmoru in Karnataka are also famous silk weaving centers. Tanjore is specialized in weaving the all over gold sarees used for weddings and temple uses. Molkalmoru has its own distinct tradition of simple Ikat weave combined with a rich gold border carrying stylized motifs.

Folk Embroidery in India

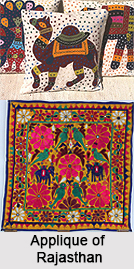

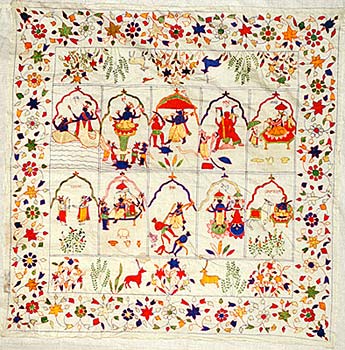

Folk Embroidery in India is closely associated with the native culture, religion, and environment of the places. In India, embroidery work is done by the folk women of the region. The Rabaris of Kutch district in Gujarat does some of the finest embroidered decorations for the camel. The embroidery has different divisions among which applique work called Dharaniya is famous in all over the country. Embroidered Torans are put on the walls during festivals. The Mutwa women of the Banni area of Kutch have a distinct style of embroidery. Bikaner has a distinct style of embroidery, which is prepared on woolen ordhnis with woolen thread. They stimulate the Bandhani effect.

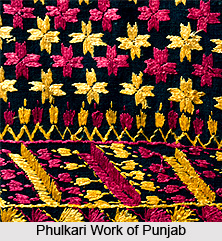

Punjab is the abode of Phulkari work. The hill areas of Himachal Pradesh produce double-sided embroidery known as Chamba Rumal. This may be of the simple folk type or the classical form, which has simplified versions of miniature paintings of Pahari. Appliqué work of Odisha and embroidery work of Bihar are famous for their creations. The Kasuti embroidery of Karnataka is a stylized form with stitches based on the texture of the fabric. Negi, Gavanti and the Menthi are the three different types of stitches used. Embroidered bead work is another distinct work of Indian weaving and dyeing craft.

Punjab is the abode of Phulkari work. The hill areas of Himachal Pradesh produce double-sided embroidery known as Chamba Rumal. This may be of the simple folk type or the classical form, which has simplified versions of miniature paintings of Pahari. Appliqué work of Odisha and embroidery work of Bihar are famous for their creations. The Kasuti embroidery of Karnataka is a stylized form with stitches based on the texture of the fabric. Negi, Gavanti and the Menthi are the three different types of stitches used. Embroidered bead work is another distinct work of Indian weaving and dyeing craft.

Shawl embroidery in India

The weaving and dyeing craft in India includes the rich tradition of shawls which are made of superfine quality wool with intricate designs and excellent workmanship. Kashmir is the workshop of a range of shawls like the Kani shawl, the double colored Pashima, the soft Santoosh, the majestic woolen shawl, the Dhussa, the men`s long shawl with its woven border and the fine Ambli or embroidered shawls. The intricate designs of Kani shawls, the double-sided shawl called Dorukha, the Aksi shawl are exemplary of the creativity of the people of Kashmir. The Himalayan region also produces many other varieties of shawls and tweeds for local usage. The shawls carry motifs inspired by the Buddhist traditions, the swastika, etc.

The weaving and dying craft in India has gained popularity for its creative and intricate designs with material of good quality. In recent times the items that are made out of weaving and dyeing process have made their way to international markets. The government has taken necessary initiatives for promoting this craft in all over India and abroad.

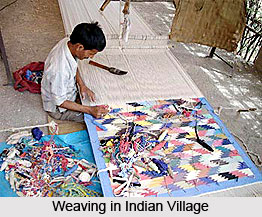

Weaving in Indian Villages

Weaving is an ancient art of making cloth and other fabrics and the Indians have been expert of weaving since the ancient period. Weaving is the process of making cloth, rugs, blankets and other products by crossing two sets of threads over and under each other. Weaving in Indian villages has been a hobby for several centuries now. Weaving has also become a major industry in the contemporary period. Weaving in Indian villages is done using threads spun from natural fibers like cotton, silk and wool and also using the synthetic fibers like nylon and Orlon.

Weaving is an ancient art of making cloth and other fabrics and the Indians have been expert of weaving since the ancient period. Weaving is the process of making cloth, rugs, blankets and other products by crossing two sets of threads over and under each other. Weaving in Indian villages has been a hobby for several centuries now. Weaving has also become a major industry in the contemporary period. Weaving in Indian villages is done using threads spun from natural fibers like cotton, silk and wool and also using the synthetic fibers like nylon and Orlon.

The Indian hand woven fabrics have been famous all over the world since times immemorial. The ancient Indian cotton-fabric Muslin was considered one of the most unique creations of Indian weavers. India was also one of the major exporters of textiles to most parts of the civilised world in the ancient period. However, in contemporary India, weaving is not limited to cloth and textile products. It plays an important part in manufacture of screens, metal fences and rubber tire cord.

Weaving in Indian villages is considered one of the largest cottage industries. Several people are engaged in weaving cotton, silk and other natural fibres and not a single village can be found in India, where the weavers do not live. Various types of weaving are done in the villages of India. Some of the most popular types of weaving in Indian villages include cotton fabrics, patola weaving, ikat fabrics, phulkari, carpet weaving, embroidery, sanganeri prints, chindi dhurries, batik sarees, himroo, hand block printing, etc.

Different region of India is famous for different types of weaving. The villages of Tamil Nadu are famous for a special kind of weaving named Madras Checks. The ikat fabrics are the pride of the villages of Andhra Pradesh and Orissa and in the villages of Uttar Pradesh, the Brocades and jacquards are famous. The villages of West Bengal are famous for weaving the fabrics like Daccai, Jamdani, Taant, etc. and the villagers in Punjab are expert in weaving Phulkari. The other famous weaving styles found in the villages of India include Chanderi pattern in Madhya Pradesh, Baluchar, Surat tanchoi, Benarasi, etc. On the other hand, people in the villages of Jammu and Kashmir are involved in weaving the world famous Pashmina and Shahtoosh shawls. The villages of India are famous all over the world for producing the famous fabrics like mulberry silk, tasser (tussore), eri and muga as well.

Apart from weaving, people in the Indian villages are also involved in other occupations like dying, designing, etc. Weaving in Indian villages is one of those rare assets for which India can feel proud of.

Weaving in Kerala

Traditional handloom weaving dominates Kerala`s textile industry and forms a major part of Kerala"s identity. It provides livelihood to almost 2 lakh weavers in Kerala, 75% of them in co operative line, thus supporting Kerala"s economy. It"s handloom fabrics are recognized throughout the world for their quality, variety, unique designs and strength. It is even difficult to recognize whether the products are hand woven or electrically woven. Kuthampully, Balaramapuram and Chendamangalam are the three major weaving centres in the state. Kerala State Handloom Development Corporation provides material and financial support to the weavers individually.

Traditional handloom weaving dominates Kerala`s textile industry and forms a major part of Kerala"s identity. It provides livelihood to almost 2 lakh weavers in Kerala, 75% of them in co operative line, thus supporting Kerala"s economy. It"s handloom fabrics are recognized throughout the world for their quality, variety, unique designs and strength. It is even difficult to recognize whether the products are hand woven or electrically woven. Kuthampully, Balaramapuram and Chendamangalam are the three major weaving centres in the state. Kerala State Handloom Development Corporation provides material and financial support to the weavers individually.

Process of Handloom Weaving in Kerala

Weaving is the process of passing a thread cross-wise (the weft) through alternate lengths of thread (the warp), creating the fabric. On a handloom, this is done by hand rather than being driven by electrical power.

The main communities in Kerala engaged in weaving are Saliyas and Devangas. Handloom weaving is mainly concentrated in villages of Kerala and this traditional skill is passed down from one generation to another. The weaving is done in homes or collective weaving sheds by both men and women. The weavers have formed co operative handloom societies to provide major supplies in terms of yarns, weaving equipments and technical information. Pit looms, frame looms and jacquard or dobby looms are usually used for weaving.

The yarn is given a scouring treatment in closed earthen or iron vessels. The scouring is done with caustic soda and soda ash and is steeped over a night. Then the following day the yarn is taken out and washed in water. A half bleaching is given to the yarn if it is intended for dyeing pastel shades. Bleaching agents used in this process are sodium hypochlorate or hidrogen peroxide. The bleached yarns are further brightened by optical brightening agents namely tinopal and ranipal. Another round of souring treatment with hydrochloric acid is done to control its pH value. Natural dyes, reactive, vat and direct dyes are used in the process. If the yarn is single count like 10S or 20s, it is sized using starch. Then the warping machines are used to prepare the warp yarn in sections or vertically. The warp yarn is tightly wound on wooden beams and fitted into looms. Bamboo reeds and metallic reeds are used for denting the warp.

Handloom Products of Kerala

Balaramapuram Sarees, Kuthampully Sarees, Kannur Shirtings and furnishings, Alappuzha Coir Mats, Turkish Towellings and carpets have become Kerala"s identity. Typical hand woven costumes worn in Kerala are Thorthu, Lungi, Saree and Dhoti.

Thorthu is a towel fabric made of cotton yarn. Kaili or Lungi is made of cotton and sometimes in poly cotton blends too. It is worn by the gents of Kerala. It is designed in checks or stripes of vivid colour combinations. Saree is woven by using fine yarns. It is worn by ladies. Kerala sarees are well known throughout the world. What makes Kerala sarees unique is the fact that they are hand woven, made out of 100% unbleached cotton and have off white color. Fineness of count in weaving is also characteristic of a typical Kerala saree. Double Mundu or Doudle Dhoti has a small border and cross border. Dark colours are used for these borders. The body of the Dhoti is in off white colour. It is a formal wear for men. Cotton and linen are used to make bed sheets and pillows in fly shuttle frame looms and jaquard looms.

Thorthu is a towel fabric made of cotton yarn. Kaili or Lungi is made of cotton and sometimes in poly cotton blends too. It is worn by the gents of Kerala. It is designed in checks or stripes of vivid colour combinations. Saree is woven by using fine yarns. It is worn by ladies. Kerala sarees are well known throughout the world. What makes Kerala sarees unique is the fact that they are hand woven, made out of 100% unbleached cotton and have off white color. Fineness of count in weaving is also characteristic of a typical Kerala saree. Double Mundu or Doudle Dhoti has a small border and cross border. Dark colours are used for these borders. The body of the Dhoti is in off white colour. It is a formal wear for men. Cotton and linen are used to make bed sheets and pillows in fly shuttle frame looms and jaquard looms.

Ayurvastra or healthy fabrics are now dominating the attention of handloom weavers in which dyeing is done with Ayurvedic herbs and plants not synthetic chemicals. It is manufactured and exported by a 50-year-old Balaramapuram handloom firm Kairali Exports. It is aimed at creating eco-friendly wellness textiles. This effort was initiated by Department of Industries and Commerce and the Department of Government Ayurveda College.

Problems Faced by Handloom Industry in Kerala

A study on handloom industry in Kerala conducted by the Evaluation Division of the State Planning Board specified the problems faced by this industry. Some of the major factors enumerated are indebtedness of weaving societies, shortage of working capital, pending arrears from apex bodies and supply of low quality raw materials from various agencies.

Other general problems highlighted by this study are lack of skill-development training programmes, labour turnover due to excessive physical labour, competition from high quality textile fabrics offered at cheap rates, power looms, dilapidated work sheds, old looms, time lag in modernising the handloom technology and time lag in total wage payment to the workers.

To deal with these problems, Kerala State Handloom Development Corporation (KSHDC) was established to provide regular employment to the weavers in Kerala and improving their standard of living, but it is not evident in their socio-economic conditions. The Government of India also stepped in to improve the conditions of the Kerala handloom industry, in terms of a new scheme called Deen Dayal Hathkargha Prothsahan Yojana (DDHPY). But this effort is not sufficient as the schemes of State would provide more supplements to meet the inadequacies in the quality and wages of people of Kerala.

Related Articles:

Kerela

Sarees of South India

Costumes of Kerala

Ksavu Sarees

Lungi

Dhoti

Cotton Fabric

Weaving in North East Indian States

Weaving is a traditional occupation for a broad range of social groups in North East Indian states like Arunachal Pradesh, Assam, Manipur, Meghalaya, Mizoram, Nagaland, Tripura and Sikkim. Each tribe of North East Indian states excels in the craft of weaving. Every village house hold has its own indigenous weaving style. Despite fulfilling the basic clothing needs at home, or for ceremonial occasion or as a decorative piece, the hand-woven textile plays a significant role in making social and cultural distinctiveness, rituals and surroundings.

Weaving is a traditional occupation for a broad range of social groups in North East Indian states like Arunachal Pradesh, Assam, Manipur, Meghalaya, Mizoram, Nagaland, Tripura and Sikkim. Each tribe of North East Indian states excels in the craft of weaving. Every village house hold has its own indigenous weaving style. Despite fulfilling the basic clothing needs at home, or for ceremonial occasion or as a decorative piece, the hand-woven textile plays a significant role in making social and cultural distinctiveness, rituals and surroundings.

Weaving is carried out throughout the North East with traditional techniques. It is unique so far as the method of ginning, spinning and weaving is concerned. The hill tribes use small "loin loom" for weaving. Some tribes of Brahmaputra Valley such as the Dimasa Kachari, Bodo Kachari and Mishings use a kind of "fly-shuttle loom". The Nocte, Nyishi and Khasi have lost the art of weaving. They depend either upon the neighbouring tribes or the market of the plains.

Various Textiles of North East India

Various Textiles of North East India

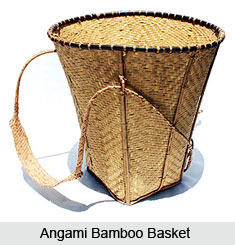

Weaving is the exclusive monopoly of the womenfolk among all the tribes of the region. The tribal weavers prepare varieties of textiles. Some of them are extremely colourful. The textile products such as loincloth, shawl, skirt, sash, jacket, bag and rug are typical of the region. For example, the shawls and loincloths of the Nagas, skirts of the Mizos, Garos, Mishmis and Adis have distinctive features of their own.

In Meghalaya, the Khasi and Jaintia have certain original designs in handloom fabric, but unfortunately they are on the decline.

In Assam, the Bodos are experts in rearing indigenous variety of cocoon. It is used for manufacturing Assam silk and "Eri" cloth. They also use floral designs.

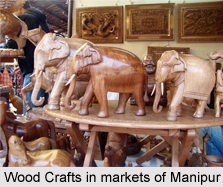

The Manipuris are also well known for their art of weaving, using traditional techniques. The Manipuri women are familiar with the process of dyeing. They use plants and some varieties of clay.

In Arunachal Pradesh, weaving is relatively less developed. The textile pattern found in Arunachal Pradesh is of geometric pattern with zigzag lines and angular designs. Contrast and combination of colours are quite popular.

The Nagas are famous for their shawls. In some tribes like the Ao Naga, three pieces are woven separately and stitched together. The central part is more decorated than the other two. Naga shawls range from a very simple white cloth to elaborately designed warrior"s or rich person`s shawls. Each Naga tribe has its own shawl with its own design.

Weaving in Rajasthan

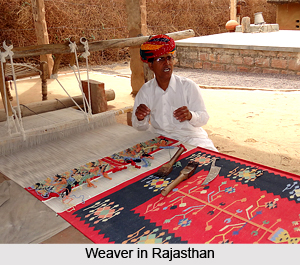

The art of weaving in Rajasthan has been practiced since ages and presently the art has acquired an iconic status in the region. The art of interlacing yarns, the warp and the weft has been well known in Rajasthan for centuries and hand-weaving is probably as old as civilisation itself.

The art of weaving in Rajasthan has been practiced since ages and presently the art has acquired an iconic status in the region. The art of interlacing yarns, the warp and the weft has been well known in Rajasthan for centuries and hand-weaving is probably as old as civilisation itself.

History of Weaving in Rajasthan

Ancient terracotta spindles and fabric, excavated from the Indus Valley civilization, are best evidences to the familiarity of the crafts of spinning and weaving. Weaving in India is predominately a cottage industry and in the state of Rajasthan, the village weaver has been the community"s sole source of fabric. The loom has held a fundamental position in the social, economic and cultural lives of the people.

Effects of Urbanisation on Weaving in Rajasthan

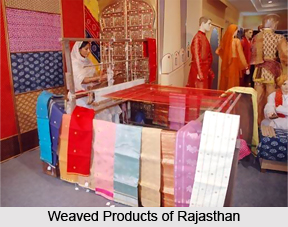

With the advent of modernisation and industrialisation of the Indian textile sector, mill-made fabrics have made severe incursions into the village weavers" traditional monopoly. The unique beauty of the Khaadi, Reza and fine Mathania Mulmul from Rajasthan, is becoming rare with the passing years. Powerlooms are fast replacing handlooms in most urban and rural areas. However, hereditary weaving-skills live on in many families in Rajasthan and economically viable products like Kota dona, pattus, durries, jajams and pile carpets, in traditional and contemporary designs are still woven in the colourful state of Rajasthan.

Process of Weaving in Rajasthan

Knowledge of the principles of weaving is found even amongst the most ancient people of Rajasthan. The process itself is simple and consists of 4 basic steps, irrespective of the kind of loom, level of technology or the pattern to be woven. The basic steps of weaving in Rajasthan are shedding, picking, beating and taking up and letting off.

Shedding is the process of raising or lowering the warp yarn by means of harness and heddles to create a shed. The weft is passed through this shed in a process that is known as Picking. This process is followed by Beating, in which the weft or filling yarn is evenly packed and made compact with a comb-like structure, called the "Reed". Once the primary motion is complete, newly formed fabric is rolled on to the cloth beam and fresh warp is released from the warp beam. This taking up and letting off is the "secondary motion" in the weaving process that is prevalent in Rajasthan.

Final Product of Weaving in Rajasthan

The village weaver in Rajasthan traditionally produces 2 types of cotton cloth, the Khaadi and the Reza. These are woven either as yardage or a finished garment, like an Odhna or a Dhoti. Khaadi is made from hand spun yarn in a plain weave, while a basket weave is employed for the thicker Reza fabric. These fabrics are then dyed and patterned as required.

The art of weaving has been epitomizing the culture of Rajasthan since decades. However, many modern mechanisms are slowly entering the weaving market of Rajasthan, but the demand for Khaadi and Reza in original form has yet not stooped low.