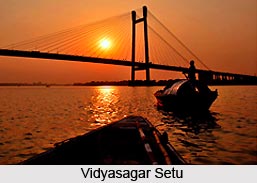

Vidyasagar Setu is also famous as the Second Hooghly Bridge or `Dbitiyo Hugli Setu`. It is a link between Kolkata and the area of Howrah in the state of West Bengal. Vidyasagar Setu measures about 823 metres in length and is considered to be amongst the longest bridge in Asia. The bridge had been named after Pandit Ishwar Chandra Vidyasagar and the approximate expenditure incurred to construct this bridge is about 3.88 billion. After the construction of the Howrah Bridge which is also known as the Rabindra Setu, The Vidyasagar Setu was the second bridge which was built over the River Hooghly. The construction finally concluded in the year 1943. The Hooghly River Bridge Commission was granted the commission to complete building this bridge on 10th October 1992 and its construction commenced on 3rd July 1979. Nearly 30, 000 vehicles commute with the aide of this bridge every day, which is far lesser than the overall capacity of the bridge which equals to 85, 000.

History of Vidyasagar Setu

History of Vidyasagar Setu

With the overwhelming population explosion in the city of Kolkata, post the Indian independence, Vidyasagar Setu was burdened by a maddening amount of traffic mess which consisted of over 85, 000 vehicles plying over the bridge daily. This prompted the immediate planning of a brand new bridge across River Hooghly in order to join the main metropolitan cities of Mumbai, Chennai and Delhi through some national highways. On 20th May, 1972, Indira Gandhi had been invited to lay the foundation stone of this beautiful bridge. This bridge took as much as 22 years to be completed. By 10th October, 1992, Vidyasagar Setu became the longest bridge in the entire world. On 3rd July, 1979, full fledged construction work had been initiated on the bridge, particularly on the side of the Calcutta banks. During this time, Vidyasagar Setu came to be known as the third largest bridge in the world.

Architectural Features of Vidyasagar Setu

Vidyasagar Setu possesses 121 cables, arranged in a system of fans and employing steel pylons which have a height of 127.62 metres and an average length of 823 metres. Composite concrete, enforced with steel has been utilized to manufacture the deck portion of this bridge. The bridge measures about 35 metres in width and is also equipped with a footpath which is 1.2 metres wide. The region of deck over the main area of the bridge is about 457.20 metres while the two other spans on its side measure about 182.88 metres in length. Schlaich Bergermann & Partner was the company which was responsible for designing this bridge, while the bridge`s construction was reviewed by Freeman Fox & Partners and also Bharat Bhari Udyog Nigam Limited. Braithwaite, Burn and Jessop (BBJ) conducted the construction of Vidyasagar Setu.

The design of this bridge comprises of a different design, as compared to other bridges and the process of live load composite construction has been used while building this bridge. A grid system of girders which have been placed at 4.2 metres, during its construction, from centre to the centre. The pylons of the bridge were created with the help of a deck crane which had a capacity of 45 tonne. Bolts are used to connect the piers of the deck. Steel boxes which measure 4X 4 metres have been employed on both the sides of the spans. Cranes of 75 MT and 50 MT have also been utilized for installing the six pylons on the side of the Vidyasagar Bridge which is present on the Calcutta bank end. Dywidag rods have been used to anchor the pylon heads of the bridge. In order to ease the process of lifting the bridge, winches, snatch blocks and sheave blocks are the various things which have been used. The voids of the bridge were filled with polyethylene (HDPE) tubes.

Prototype wind tunnel examinations have been carried out at the Indian Institute of Sciences in Bangalore to ensure the efficiency of Vidyasagar Setu. Bearings used in horizontal and vertical directions, along with collars at both the end piers ensures the stability of the bridge against the constant movement and tremors, caused by the incessant movement of innumerable quantity of vehicles over it. Other necessary elements which have been employed while constructing Vidyasagar Setu involve electric lines, crash barriers, telephone, gas service support mechanism structures, lightning arresters, handrails, lifts inside pylons and also a gallery for maintenance.