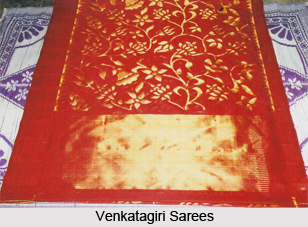

Venkatagiri Sarees are not only the pride of Andhra Pradesh, but are also a part of its cultural heritage. In fact, it was registered as one of the geographical indication from Andhra Pradesh by Geographical Indications of Goods (Registration and Protection) Act, 1999. Venkatagiri is a small town in Nellore district of Andhra Pradesh state of India, which is famous for the production of Venkatagiri sarees. These sarees are primarily handloom sarees. The art of weaving and dyeing of cotton is a 5000 year old art in India. In fact, this art was invented in India and then pervaded Egypt and China. Venkatagiri sarees are also product of the weaving and dyeing technique. These ethic sarees are renowned for excellent craftsmanship as weavers indulge themselves in painstaking labour and fine weaving. They are also praised for their remarkable quality, well defined designs and variety. The art of creating these sarees is passed on from one generation to another. These sarees can also be found in Sengunthapuram, Variyankaval, Elaiyur, Kallathur, Andimadam and Marudhur villages.

Venkatagiri Sarees are not only the pride of Andhra Pradesh, but are also a part of its cultural heritage. In fact, it was registered as one of the geographical indication from Andhra Pradesh by Geographical Indications of Goods (Registration and Protection) Act, 1999. Venkatagiri is a small town in Nellore district of Andhra Pradesh state of India, which is famous for the production of Venkatagiri sarees. These sarees are primarily handloom sarees. The art of weaving and dyeing of cotton is a 5000 year old art in India. In fact, this art was invented in India and then pervaded Egypt and China. Venkatagiri sarees are also product of the weaving and dyeing technique. These ethic sarees are renowned for excellent craftsmanship as weavers indulge themselves in painstaking labour and fine weaving. They are also praised for their remarkable quality, well defined designs and variety. The art of creating these sarees is passed on from one generation to another. These sarees can also be found in Sengunthapuram, Variyankaval, Elaiyur, Kallathur, Andimadam and Marudhur villages.

History of Venkatagiri Sarees

The Venkatagiri sarees are known to exist since 1700, which is marked by the rule of Venkatagiri. The Velugoti dynasty of Nellore and the Bobbili and Pithapuram dynasties also gave impetus to the production of these sarees. They were exclusively weaved for a specific section of society, like the royal princesses and the zamindars and the amount they used to receive in return was sufficient for the whole year. At that time, royalty was thus in part, defined by these sarees.

Stages of Production of Venkatagiri Sarees

The production of Venkatagiri saree is divided into various stages. Firstly, the raw materials such as cotton in a particular form called the hank form, silver and gold zari`s along with naphthol and vat dyes are acquired in the required amount. Then the cotton purification process is undertaken. Here, the hank cotton is boiled to get rid of impurities. It is then soaked overnight and rinsed so that it is ready for the dyeing process. During the dyeing process, vat and naphthol dyes are used in case of coloured sarees, whereas, the bleaching technique is used in case of white sarees. The yarn in hank form is dried on bamboo sticks. Then the warp and weft technique is used. Instruments like charka, shift bamboo and bobbin are used to create the warp, while, the weft is made with the help of a pirn. The warp extension, spraying of rice conjee, ensures suitable weaving followed by drying. This technique is called street sizing. The weaving process usually involves the warp and weft technique, which is replaced by jacquard weaving sometimes. Once the weaving is done, the design aspect of the saree becomes the prime focus. The designs on these sarees are divided into two types, namely, human design and graph paper design. The woven cloth then undergoes cutting according to the goods demand. Once the saree is prepared, it is inspected by the experienced weavers. The flaws in the saree are then rectified or the saree enters the next stage of distribution and marketing. These sarees are then ready for display and sale in showrooms and today they are also available online.

Features of Venkatagiri Sarees

Silk or cotton fabric with zari is utilized to weave Venkatagiri sarees. The best known in cotton is gadiwal, wainarpati, nainder and venkatagiri. The gaidwal and wainarpati have a thick cotton body, often worked in checks with a contrasting rich silk border and pallu worked in gold. Nainder used to be famous for its very fine quality cotton saris richly worked in gold thread, with a broad contrasting silk and gold border. Various flora, fauna and nature elements are designed on these sarees to make them look elegant and attractive.

Types of Venkatagiri Sarees

A variant of Venkatagiri saree is called the jamdani zari saree. It has "Jamdani" prints on a cotton base and a zari border. This type of Venkatagiri saree is generally used for festive clothing.

Its handloom silk variant made from gold or silver zari is graced by motifs of mango, parrot, animals and birds.

Promotion of Venkatagiri Sarees

The local craftsmen today have started producing these sarees utilizing the power looms. Thus, these sarees are also electrically woven, which will ensure faster production of these sarees. Department of Handicrafts under Ministry of Textiles (India) is responsible for promoting the craftsmen and powerloom production of these sarees. Also, there is an Institute of Handloom Technology, which teaches the technique of weaving thus helping people who wish to make a career in handloom fabrics. The graduates who wish to stay can pass on their knowledge regarding new designs and modern techniques of Venkatagiri saree production to the freshers.

Related Articles:

Indian Sarees

Sarees of South India

Designs in Indian Sarees

Indian Silk Sarees

Traditional Indian Sarees

Sarees and Indian Women

Colour Symbolism in Indian Sarees

Fabric of Indian Sarees

Indian Clothing

Types of Clothing in India