Leather products have been known since several centuries. Various mythological tales mention about leather goods used by even gods and goddesses. The use of dried hides (animal skin) in making leather items was well known since ancient times, though the process of tanning was developed much later perhaps by accident. During the earliest eras, the hides were dried in the sun and then converted into designed goods. Such hides were harder, durable but rarely comfortable. These hides were used to cover the waist and below even during the Stone Age. Dried hide during the later period was found to be useful for preparing shields to protect from enemy arrows. Subsequently, the tanning process was developed with initial usage of extract from barks, wood and leaves of trees in tanning hides into leather. This process was known as vegetable tanning, still practised in certain parts of India and third world countries. After an initial setback, the process is regaining popularity being considered eco-friendly. Thereafter came the process of Chrome tanning, which involves the chemical tannin in converting animal skin into leather, giving much better and more comfortable leather, although polluting the atmosphere as well as water sources. The pollution control boards have presently put various restrictions and tanning fluids must necessarily be treated in accordance with latest regulations. Thereafter, the process of synthetic tanning was introduced, giving even finer leather with greater risk of pollution.

India is well known for leather products and out of the country"s total exports, leather goods occupy a considerable share. India has the tradition of all types of tanning discussed above. There are numerous well known and globally reputed units in India producing leather goods. In most of the cases, leather goods were produced by a class of people called "Chamars" (Muslims) and leather artisans are usually lowly placed in social hierarchy. In the northeast state of Manipur, however, such class difference is usually absent. Though the Lois are considered low in hierarchy, they are not considered untouchables as the Chamars are. The state has had the tradition of processing leather goods since long, having developed leather technology in their own way. Scholar T. C. Hodson after his visit to Manipur reported in his compilation "The Meitheis": "In leather manufacturers, I am told, there has been of late years a great improvement. Formerly tannin was a matter of great difficulty, and the results inferior. Now they use a bark of a tree (name unknown to me), which is found in plenty in the jungles; by this they make leather superior to any formerly known in the country, they also enamel the leather very nicely in black. The skins used are those of deer and calf, and the articles made, saddles, shoes, belts, pouches etc., for the use of the troops."

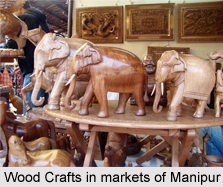

Products made of Leather in Manipur

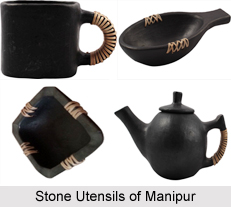

In Manipur, leather craft has evolved with time. During the ancient period, the leather craft of both the hills and the valley was identical. They had plenty of hides since they used to consume animal meat, with or without hide (some Naga tribes had the habit of consuming hides with meat). The scenario changed after 1734 AD with Vaishnavism bringing in changes in food habits. However, leather craft continued as the Meitheis bought hides from the Lois and the tribes. During yesteryears, leather products were made by drying hides.

In order to know the leather craft goods of Manipur, it is necessary to understand their game Sagol Khangjei, which in the contemporary world is known as the game of Polo or hockey on horse back. It is said that the game was introduced during the reign of King Khagemba during the 15th or 16th century. Since saddles were needed by the riders or players, it is natural that leather craft was known during the period. The modern game Polo has in fact developed from Sagol Khangjei of Manipur. T. C. Hodson described these saddles in "The Meitheis" as to being large, light and peaked both in front and rear ends, their most curious feature being the addition of a pair of leather flaps projecting around the legs of the rider and giving some protection from a blow. The flaps, made of enamelled leather, are fastened underneath the stirrup irons. This observation indicates the existence of leather craft in Manipur since the 15th century and developed enough to produce saddles by then. Enamelling might have arisen later.

Before guns were used as weapons, bows, arrows, spears, "daos" and swords etc. were existent in India like any other country and in Manipur, both the people of the valley and the hills used spears, bows and arrows for hunting as well as in war. While attacking the enemies, they also needed shields to defend themselves. Regarding their shields, Hodson remarked them to be round and made of buffalo hide studded with brass knobs, sufficiently thick and strong to guard against a spear thrust. They are presently made and worn mainly on ceremonial occasions. During Lai Haraoba processions, one or two men each at the beginning and at the end with attire identical to that of Nagas, goes along with a shield made as above and a spear, supposedly as sentry or security personnel. These shields, if further developed as crafts can be highly decorative items to adorn modern drawing rooms. The crafts can be made of various sizes to secure apt market demand.

The Meitheis also developed vegetable tanning using the bark of a plant, most likely Babool growing wildly in forest, as tannin, by first using lime to remove hair and other unwanted material and then after washing the hide, thoroughly tanning it in the bark extract. The tanned leather is dried under the sun and the quality of tanning was good enough to make saddles, shoes etc. for the troops of Manipur. They developed the process and products so well that they could even get orders for supply to the British Army, against steep competition from Calcutta and Kanpur.

Post independence, a number of Manipuris were given preference for admission in leather technology colleges in Calcutta and Madras and those who came back after qualifying themselves could become catalysts for further development. In the process, a number of small scale footwear units came up. A number of shops are today found selling locally made footwear. When the Khadi and Village Industries Commission organised a small artisan course in footwear during 1984-85 at Nambol not far from Imphal, it was observed that even first generation artisans could produce goods after brief training as good as products from organised sector. This reflects the skill of the Meitheis, most of whom, however, today produce goods out of chrome tanned leather procured from outside. Vegetable tanning still continues in certain pockets, such as the foothill village of Heirok and surrounding areas. They tan the hides and produce leather craft of local need, often making them fancy by enamelling. The products though are not well known even in Manipur, but can fetch market if promoted. NGOs Heirok Khadi & Village Industries Society and Hiyanglam Rural Development Association had submitted plans to Khadi and Village Industries Commission as well as Leather Technology Mission.

Manipur had the tradition of leather craft in the valley, but it is languishing for multiple reasons. Instead of emulating modern designs and technology to compete with similar products, Manipur`s own tradition needs to be developed and such products shall get global market at premier price, being exclusive in nature as well as eco-friendly.

Related Articles:

Manipur

Crafts of Manipur

Tribes of Manipur

Leather Industry in India

Chamars

Leather Art

Nagas

Sagol Khangjei

Lai Haraoba