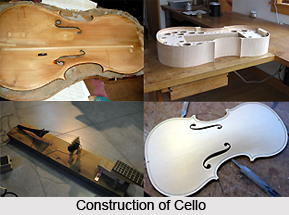

Construction of cello can be put into various steps. This instrument is characteristically made of wood, but there are other materials like carbon fibre or aluminium is also used. A conventional Cello possesses a spruce top with maple for the back, neck and sides. Other woods like the willow or poplar are also sometimes used for the sides and back. Cellos those are not so expensive frequently have tops and backs made of laminated wood. The back and the top are conventionally hand carved and are often machine-produced. The ribs or sides are made by heating the wood and also bending it around forms. The cello body has a wide top bout, narrow middle formed by two C-bouts and also wide bottom bout, with the bridge and F holes just below the middle.

Construction of cello can be put into various steps. This instrument is characteristically made of wood, but there are other materials like carbon fibre or aluminium is also used. A conventional Cello possesses a spruce top with maple for the back, neck and sides. Other woods like the willow or poplar are also sometimes used for the sides and back. Cellos those are not so expensive frequently have tops and backs made of laminated wood. The back and the top are conventionally hand carved and are often machine-produced. The ribs or sides are made by heating the wood and also bending it around forms. The cello body has a wide top bout, narrow middle formed by two C-bouts and also wide bottom bout, with the bridge and F holes just below the middle.

The back and top of the cello also has a decorative border inlay called Purfling. This is attractive and also functional. If this instrument is properly struck then it can produce the sound of a wood. A crack can form at the rim of instrument but will not spread any further. Without the purfling the cracks can spread down and up, back and top.

Neck, Pegbox and Scroll

Above the main body is the carved neck that leads to a pegbox and the scroll. The pegbox, neck and scroll are normally carved out of single piece of wood. It is attached to the neck and also extending over body of instrument out of single piece of wood. The nut happens to be the raised piece of wood where the fingerboard meets the pegbox that the strings rest on. The pegbox houses four tuning pegs one for each string. These pegs are used to tune the cello by either tightening or loosening the strings. The scroll is a conventional part of the cello and all member of the violin family.

Strings

Strings on the instrument have cores made out of gut (goat or sheep), metal or synthetic material like Perlon. Most of the modern day string instruments are wound with metallic material like aluminium, titanium and chromium.

Tailpiece and Endpin

Endpin and tailpiece are found in lower part of cello. The tail is conventionally made of ebony or another hard wood, but it can also be made of plastic or steel. It also attaches the strings to lower end of cello, and can also have one or more fine tuners. The spike or endpin is made of wood, metal or solid carbon fibre and also supports the cello in playing position.

Bridge and F-Hole

The bridge actually holds the strings together, above the cello and also transfers their vibrations to the top of instrument and sound-post inside. This bridge is actually not glued but is held by tension of strings. The f-holes which are named after its shape, are situated on either side of bridge, and allow air to move in and out of instrument as part of sound production process. The f-holes also allows to access points interior of the cello for repairs or maintenance.

Internal Features

Internally the instrument has two crucial features: a bass bar, which is glued to the underside of the top of the instrument, and a round wooden sound post, which is wedged between the top and bottom plates. The bass bar, found under the bass foot of the bridge, serves to support the cello`s top and distribute the vibrations. The sound post, found under the treble side of the bridge, connects the back and front of the cello. Like the bridge, the sound post is not glued, but is kept in place by the tensions of the bridge and strings. Together, the bass bar and sound post transfer the strings` vibrations to the top (front) of the instrument (and to a lesser extent the back), acting as a diaphragm to produce the instrument`s sound.

Glue

The cello is an instrument that is repaired and constructed using the hide glue that is strong but reversible, allowing for disassembly when needed. Tops may be glued on with the diluted glue, since some repairs call for removal of top. Theoretically the hide glue is weaker than the body`s wood so as the top or back shrinks side to side the glue holding it will let go, avoiding a crack in the plate.

Bow

Conventionally the bows are made of brazilwood and pernambuco. Both come from same species of tree (Caesalpina echinata), but pernambuco, used for higher-quality bows, is the heartwood of the tree and is darker in colour than brazilwood (which is sometimes stained to compensate). Pernambuco is a heavy, resinous wood with great elasticity, which makes it an ideal wood for instrument bows.

These bows are also made from other materials like carbon fibres, stronger than wood and fibreglass. An average cello bow is 73 cm long (shorter than a violin or viola bow) 3 cm high (from the frog to the stick) and 1.5 cm wide. The frog of a cello bow typically has a rounded corner like that of a viola bow, but is wider. A cello bow is roughly 10 grams heavier than a viola bow, which in turn is roughly 10 grams heavier than a violin bow.

Bow hair is traditionally horsehair, though synthetic hair, in varying colours, is also used. Prior to playing, the musician tightens the bow by turning a screw to pull the frog (the part of the bow under the hand) back, and increase the tension of the hair. Rosin is applied by the player to make the hairs sticky. Bows need to be re-haired periodically.