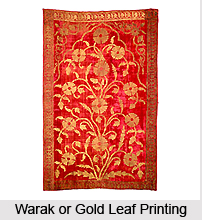

Warak or Gold Leaf Printing, a specialised form of printing in Rajasthan, is characterised by the use of gold or silver leaf, called Warak instead of the powder used in tinsel printing.

Warak or Gold Leaf Printing, a specialised form of printing in Rajasthan, is characterised by the use of gold or silver leaf, called Warak instead of the powder used in tinsel printing.

The ornamentation on cloth by Warak or Gold Leaf Printing is century old and still continues to be one of the most expensive ones in the region. In the past the privileged class all over India used it extensively but it lost much of its patronage over the chaotic years of colonial rule and at the advent of independence. However, recent times have seen a restoration of interest in Warak printing, although only a limited number of artisans still practise the method of gold leaf painting. Popular motifs for Warak ornamentation are keri-ki-bel, keri-buti, mehraab, genda, phul-ki-bel, jawar bhat, chaukhana as well as deities like Radha and Krishna.

The process of making Warak is an art in itself. Sheets of gold or silver are changed with layers of parchment acquired from sheep, goat or deer hide and lined with finely powdered soapstone. They are collected into a small parcel and firmly captured on all four sides, before being placed in a hide-pouch. The pouch in turn is then stabilized on a stone and beaten with a special mallet for about seven or eight hours. This wafer thin gold or silver leaf so produced, known as Warak, is carefully collected between sheets of kite paper. One may mention here that Warak has many uses other than the ornamentation of cloth. It is used as a therapeutic ingredient in the healing system of Ayurveda and even as garnishing on various dishes and desserts.

In Warak printing, the cloth is first laid on a padded wooden printing-table and motifs are then imprinted on to it with the help of blocks, which are generally made up of wood. Some of these blocks may essentially comprise a simple piece of wood with iron nails embedded on its surface to form a design. These blocks, however, use less Warak, so the wooden blocks are preferred as they impart a better lustre. The gold leaf printing begins with the preparation of an adhesive paste, made of safeda (fine white powder) and a resin, saresh. Each is heated to its melting limit and the two are then merged. This mixture is further overwrought in order-to remove any impurities. Finally, an adhesive paste is obtained, which will be used for printing on the fabric. Readymade paste, which has a longer shelf-life, is also present in the market. Then, a wooden block is pressed gently on the paste which is spread on the printing pad and, then, stamped onto the fabric to create a design on its surface.

After the design has been outlined on the fabric, Warak is then applied. A small pad in the shape of a little pouch is filled with cotton wool that is extensively used for this. A hand brush is used to remove all residual Warak. Finally, the cloth is glistening with a rolling pin attached with a stone or moro, which gives it a gorgeous glossy sheen. Warak printing is carried out on garments like dhotis, pichvais, safas, saris and on ceremonial altar cloth offered at temples. For instance, the Kankroli temple has an image of Lord Krishna adorning a dress with a special Warak design.