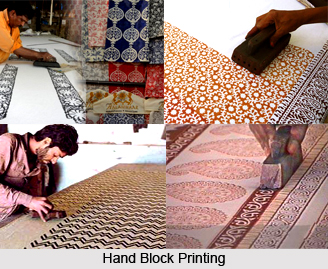

The idea of using an object to impress repeated designs on cloth can be traced to prehistoric times. The first application of colour to cloth was probably by hand. This progressed to twigs and brushes, then stamps made from clay, metal, and wood. Anokhi uses hand-carved wooden blocks to print cottons, silks, wools, and rayons. To ensure crisp carving and sharp detail, wood blocks are made by cutting into the end grain of dense woods.

Hand-block printing is an inseparable part of cultural heritage of Rajasthan. Traditionally, Sanganer produced fine small floral motifs on white backgrounds for the royal court, whilst Bagru produced simplified graphic designs for the local rural people.

The process of hand block printing is very intricate and interesting. Once the teak block has been carved, the cloth to be printed is stretched out on a table five metres long and pinned at each end to fix it. A tray is filled with the pigment and the block is placed into it to collect the accurate amount of dye.

Once the design and colours have been finalised they are given to the block-maker. He then marks the design out on a block, which is usually around 15 cms square. The number of blocks needed per design depends on the number of colours used. Colours are applied one at a time. To ensure that each subsequent colour registers properly, blocks are often cut to shape or have registration notches cut into them. The block-maker may take up to 80 hours to carve a single colour block and the printer may require upto 30 separate blocks to complete a garment or quilt.

Once the design and colours have been finalised they are given to the block-maker. He then marks the design out on a block, which is usually around 15 cms square. The number of blocks needed per design depends on the number of colours used. Colours are applied one at a time. To ensure that each subsequent colour registers properly, blocks are often cut to shape or have registration notches cut into them. The block-maker may take up to 80 hours to carve a single colour block and the printer may require upto 30 separate blocks to complete a garment or quilt.

The tray, which contains a metal grid with layers of fabric laid on top, is filled with dye. The dye soaks through the fabric, which then acts as an ink pad against which the block is to be pressed. The block is then placed carefully on the fabric and struck with the heel of the printer`s hand. The process is repeated until the entire cloth is covered. This means that the cloth can be stamped over a 1000 times for three metres. Each colour has its own block and each colour is lined up using tiny markers in the blocks. Colours can vary owing to the weather and as it is printed in five metre lengths can vary within a collection. Natural dyes are affected more by the weather and printing has to stop completely over the Monsoon season. The more colours used the greater is the time and labour required for cutting the blocks and printing the cloth.

Different dyes react in different ways and therefore have separate process when applied to fabric. Indigo dyes for example are resist-printed with a paste made from clay, wheat chaff and gum. The resist paste is printed on the cloth with a block and left to dry. This block the indigo dye from penetrating the cloth when the cloth is later dipped into the indigo vat. Once the cloth has been dyed it is washed to remove excess dye and the resist paste. Hand block printed fabrics are best washed in warm water with a gentle detergent. This ensures the colours remain rich and vibrant.